Service hotline

+0086-139-2465-7372

BLOG

In the process of precision machining service, the journey from a digital design to a physical, high-quality component is complex. At PuKong Prototype, we specialize in bridging this gap, particularly when moving from single prototypes to full-scale mass production. When working with Q345B, a versatile high-strength low-alloy structural steel known for its excellent weldability and mechanical properties , our process is designed for efficiency, repeatability, and uncompromising quality.

This article provides a detailed walkthrough of a Q345B part’s life in our facility, covering every critical step from the initial procurement of raw materials to the final packaging and shipping.

The foundation of any high-quality part is the raw material. The process begins with the procurement of certified Q345B steel. We source our material exclusively from reputable mills and suppliers, ensuring it comes with valid mill test certificates (MTC) that verify its chemical composition and mechanical properties. Depending on the part design, we order the material in the most efficient form—whether steel plates, bars, or custom-sized blocks. Upon arrival, every batch is inspected for surface defects and dimensional accuracy before being officially released into our inventory for production.

With the material ready, our engineering team takes over. Using the customer’s 3D CAD model, we begin the virtual manufacturing phase in our CAM software. This is where the strategy for the entire production run is established. We generate optimized toolpaths, select the appropriate cutting tools, and calculate the ideal feeds and speeds for machining Q345B. Crucially, this stage also involves meticulous process planning. We map out the entire workflow sequence—deciding which features will be milled, which require EDM, and the order of all subsequent surface treatments—to ensure a seamless and logical flow through the workshop.

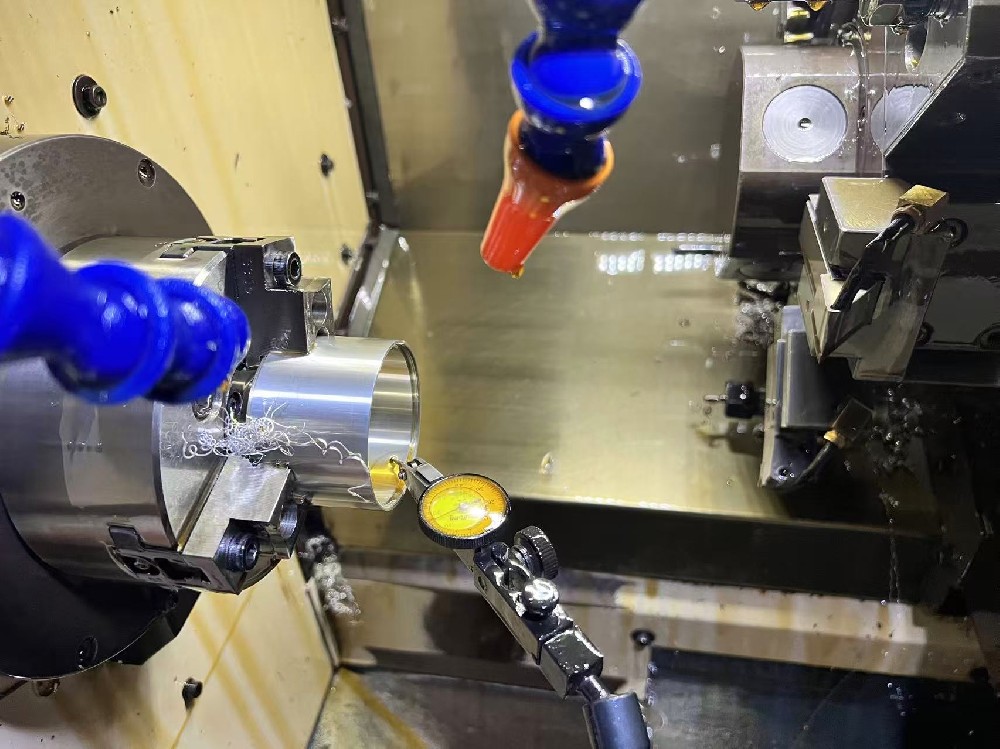

This is where the part starts to take shape. The Q345B workpiece is securely fixtured onto one of our advanced CNC machines.

CNC Turning: For parts with cylindrical features, the material rotates at high speed while a stationary cutting tool shapes the outside diameter and internal bores.

CNC Milling: For complex, prismatic parts, the workpiece remains stationary (or moves along multiple axes) while rotating cutting tools remove material to create flats, slots, pockets, and contours. PuKong utilizes 3, 4, and 5-axis CNC machining centers to handle intricate geometries in a single setup, maintaining tight tolerances down to ±0.01mm. Throughout this process, coolant is used to manage the heat generated when machining the strong Q345B steel, ensuring both tool life and surface finish quality.

When a part requires features that are impossible for a conventional milling cutter to create—such as extremely narrow slots, precise internal splines, or parts with sharp internal corners—we turn to Wire EDM. This process uses a thin, electrically charged brass wire to erode the Q345B material with incredible precision. Since Q345B is highly conductive, it is an ideal candidate for this process, which produces burr-free edges and exceptional straightness.

For blind cavities, complex shapes, or features requiring a fine surface finish deep within the part, Sinker EDM is employed. A custom-machined electrode, typically made of graphite or copper, is created in the inverse shape of the desired cavity. This electrode is then slowly fed into the Q345B workpiece submerged in dielectric fluid. Electrical sparks erode the steel, accurately transferring the electrode's shape into the part.

While many holes are machined during the initial CNC phase, secondary drilling and tapping operations are often required for specific thread depths or angles. Using dedicated machining centers or manual drill presses with precise fixtures, we create all necessary through-holes, blind holes, and threaded features, ensuring every thread pitch is accurate and clean.

Every machining operation, from milling to drilling, can leave behind sharp edges or burrs. This critical step involves skilled technicians meticulously removing these imperfections. Using hand tools, files, and specialized deburring knives, they break all sharp edges. This is essential not only for the safety of the end-user and assembly workers but also to ensure the part meets engineering specifications and is perfectly prepared for the adhesion of subsequent coatings.

After the mechanical shaping is complete, the part enters our quality control lab.

CMM Inspection: The part is secured on the bed of a high-precision Coordinate Measuring Machine (CMM). A touch probe travels across the part, taking hundreds of measurements and comparing them against the original CAD model. This verifies that all critical dimensions, hole locations, and geometric tolerances are within the specified limits.

Visual Inspection: Under proper lighting, inspectors also examine the part for any surface imperfections, tool marks, or damage, ensuring the overall appearance meets our high standards.

With the "white part" (raw machined part) approved, it moves to the finishing department. The choice of finish depends on the application, and PuKong offers a full range of options for Q345B steel:

Blackening (Black Oxide): The parts are immersed in a series of chemical baths that create a black iron oxide layer on the surface. This provides mild corrosion resistance and a sleek, matte black aesthetic often used for automotive and tooling components.

Zinc Plating (Galvanizing): For superior rust protection, the parts are electroplated with a layer of zinc. This process requires careful control, especially with Q345B, as its silicon content can affect the final appearance and thickness of the coating.

Painting (Spray Painting): Liquid paint is applied using spray guns to achieve a specific color and gloss level. This can be done manually or in automated booths for larger runs.

Powder Coating: For the most durable and uniform finish, electrostatically charged powder is sprayed onto the part, which is then baked in a curing oven. The heat melts the powder into a tough, seamless layer that is highly resistant to chipping, scratching, and corrosion.

After the surface treatment is applied, the parts return to QC for a final inspection. We verify that the coating is flawless—free of runs, thin spots, or contamination—and that the finish hasn't masked any underlying defects. This is the last line of defense to guarantee part quality.

Approved parts are now ready to be prepared for shipment. PuKong takes great care in packaging to ensure the products arrive in perfect condition.

Individual Protection: Parts are often wrapped in anti-corrosion paper or VCI (Vapor Corrosion Inhibitor) bags to protect the finish.

Cushioning: They are then nestled in foam, bubble wrap, or partitioned cardboard boxes to prevent movement and absorb shock during transit.

Outer Carton: All protected parts are placed into sturdy, double-walled cardboard boxes or custom wooden crates for heavy or large items.

Finally, the packaged goods are labeled, and shipping documentation is prepared, including packing lists and commercial invoices. We coordinate with reliable logistics partners to arrange the most efficient and secure shipping method, whether by air, sea, or land courier. The order is tracked until it reaches the customer's doorstep, completing the full-cycle manufacturing journey at PuKong Prototype.

By maintaining rigorous control over every one of these steps—from the first piece of Q345B stock to the final package on the truck—PuKong Prototype ensures that every batch of mass-produced parts meets the exacting standards of precision, durability, and quality our clients demand.

Prev:A aluminum project for a client

Next:No More

ADD:Floor 4, Yongjianhong high-tech park, No.20, Songyu road, Songgang, Baoan district, Shenzhen,China 518105

TEL:+0086-139-2465-7372

E-MAIL:enquiry@pkprototype.com