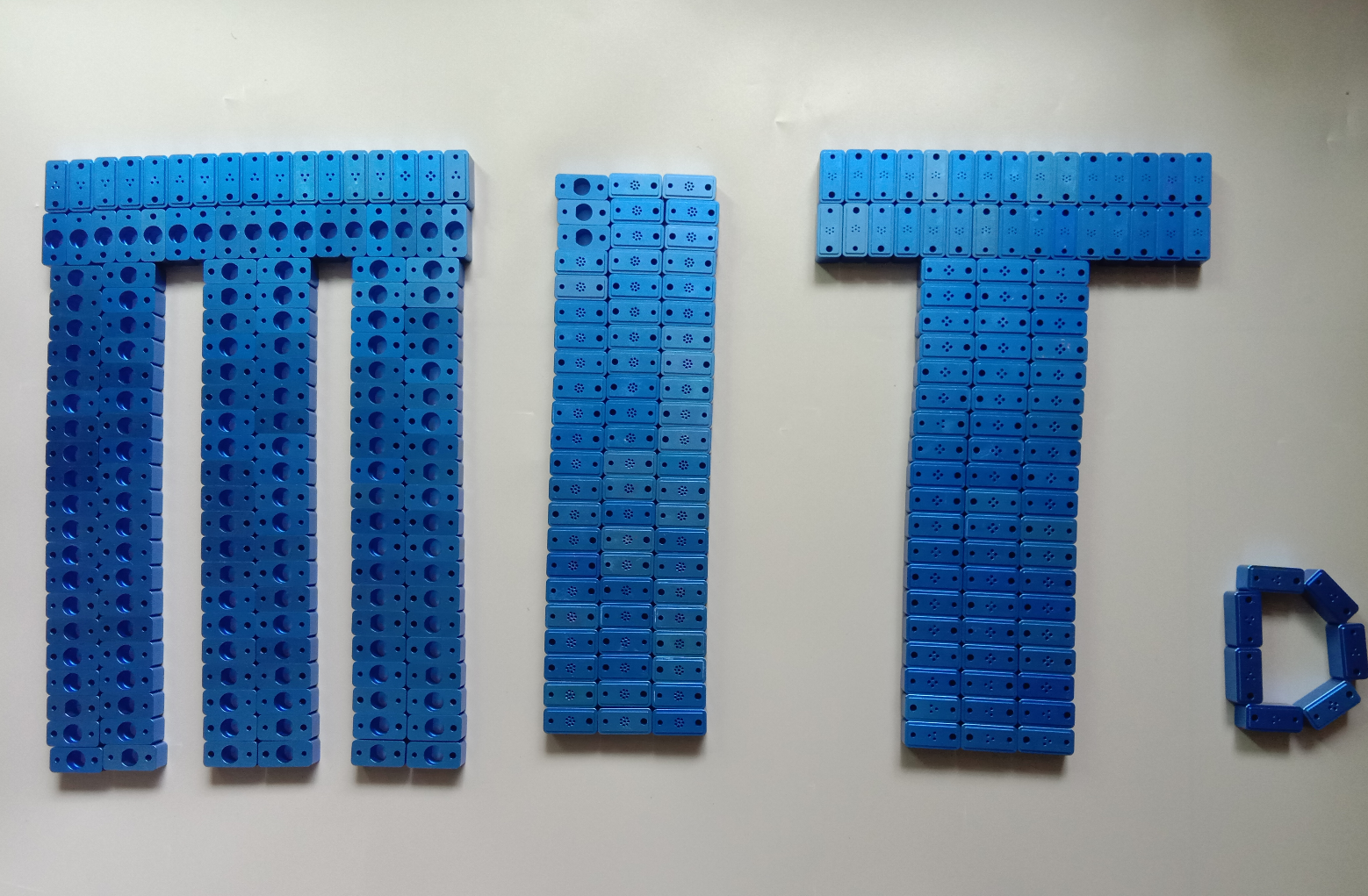

This is a low volume production aluminum project we did for a client. It is about fine cnc machined aluminum parts and blue anodised finish,it is a functional part so the surface treatment is not required(not a cosmetic part). And we have conclude the general process as below:

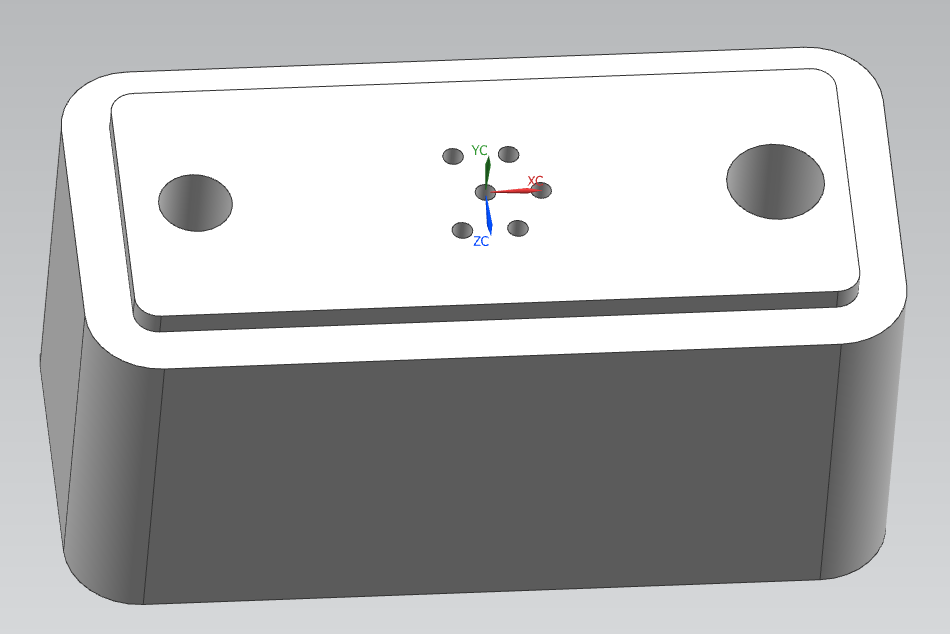

1.Programming. This cost some minutes(or hours if the geometry is much complex).

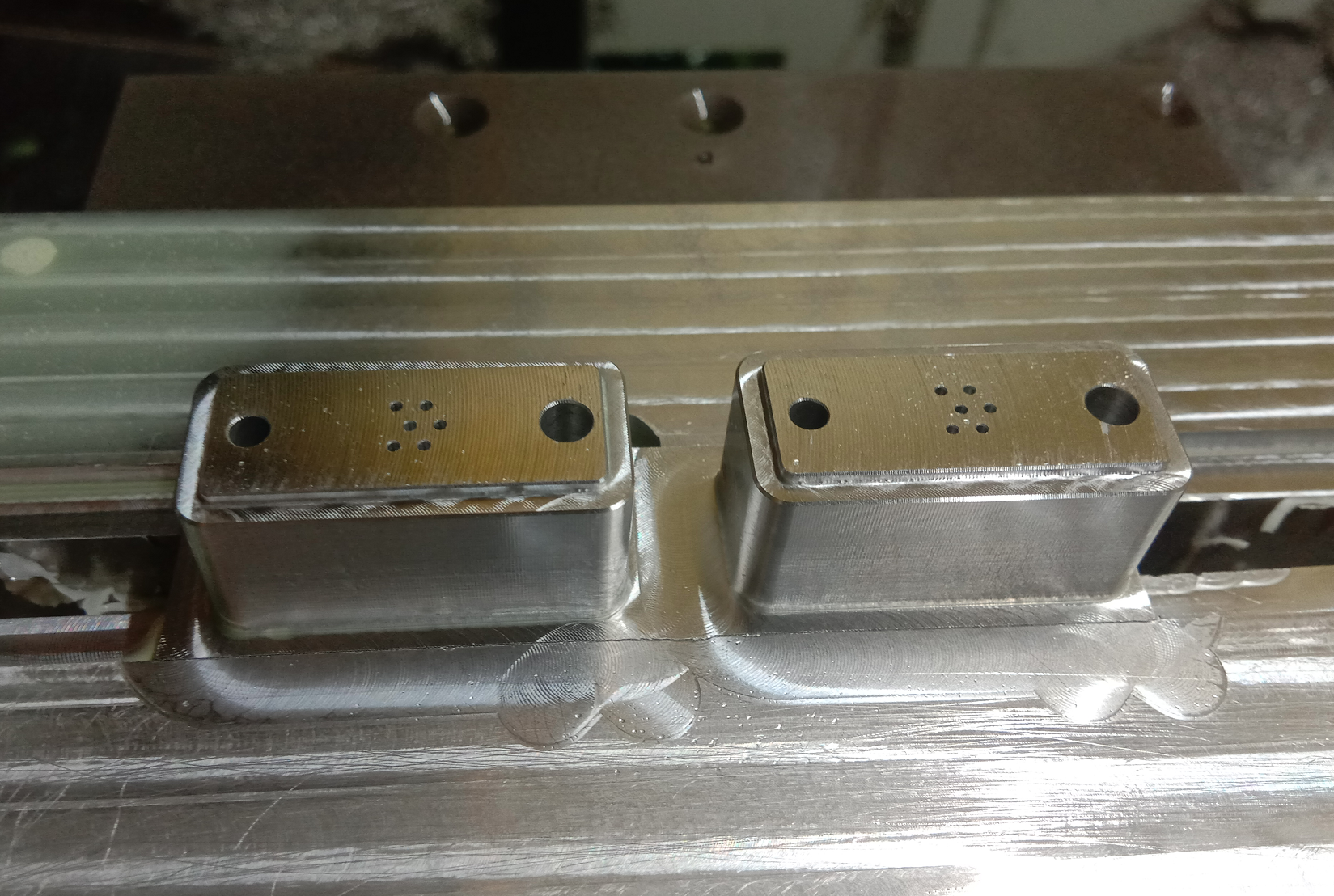

2.CNC milling machining(This usually cost some days).

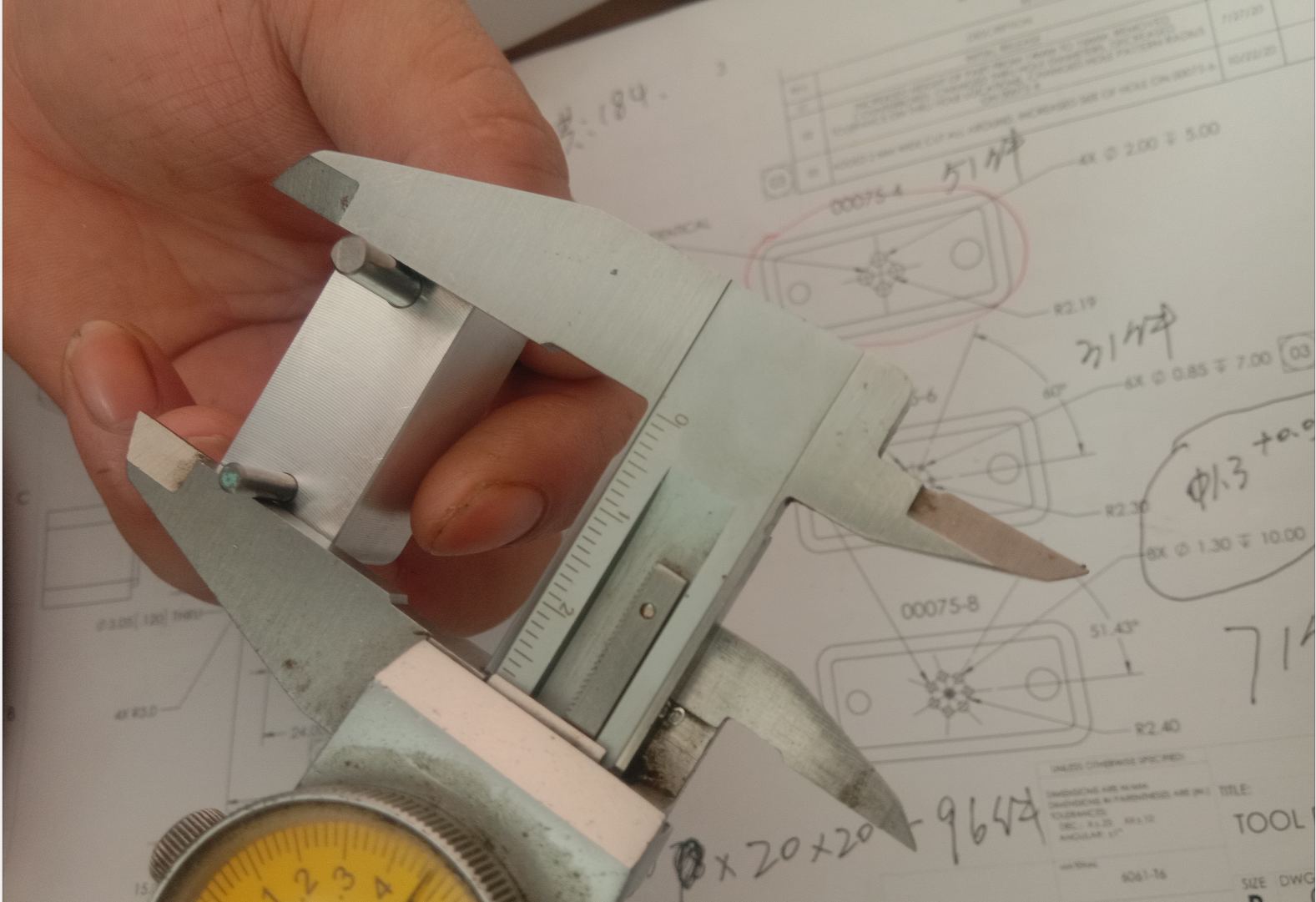

3.Quality Checking(We do this regularly during the machining process to make sure the parts are all within the tolerance).

4.Anodising(sometimes this process cost 1-2 days).

5.Quality inspection(This is the final dimension/tolerance inspection process to make sure all parts are good).

6.Packaging(To protect the part safe during the shipping)..

7.Shipping.